A realistic simulation of NFIRAOS and its instruments. At first light NFIRAOS will serve three instruments: IRIS located at the bottom, MODHIS at the top, and NSEN — a non-science instrument that will help first light activities — reaching out of the page.

A realistic simulation of NFIRAOS mounted on the Nasmyth platform. NFIRAOS can serve three instruments mounted to it. Note the reflection of the telescope truss in the foreground mirror, looking out to NFIRAOS.

A realistic simulation of TMT inside its dome. You can see the 30 meter primary mirror and the tertiary mirror as well as the back of the secondary mirror at the top of the artwork.

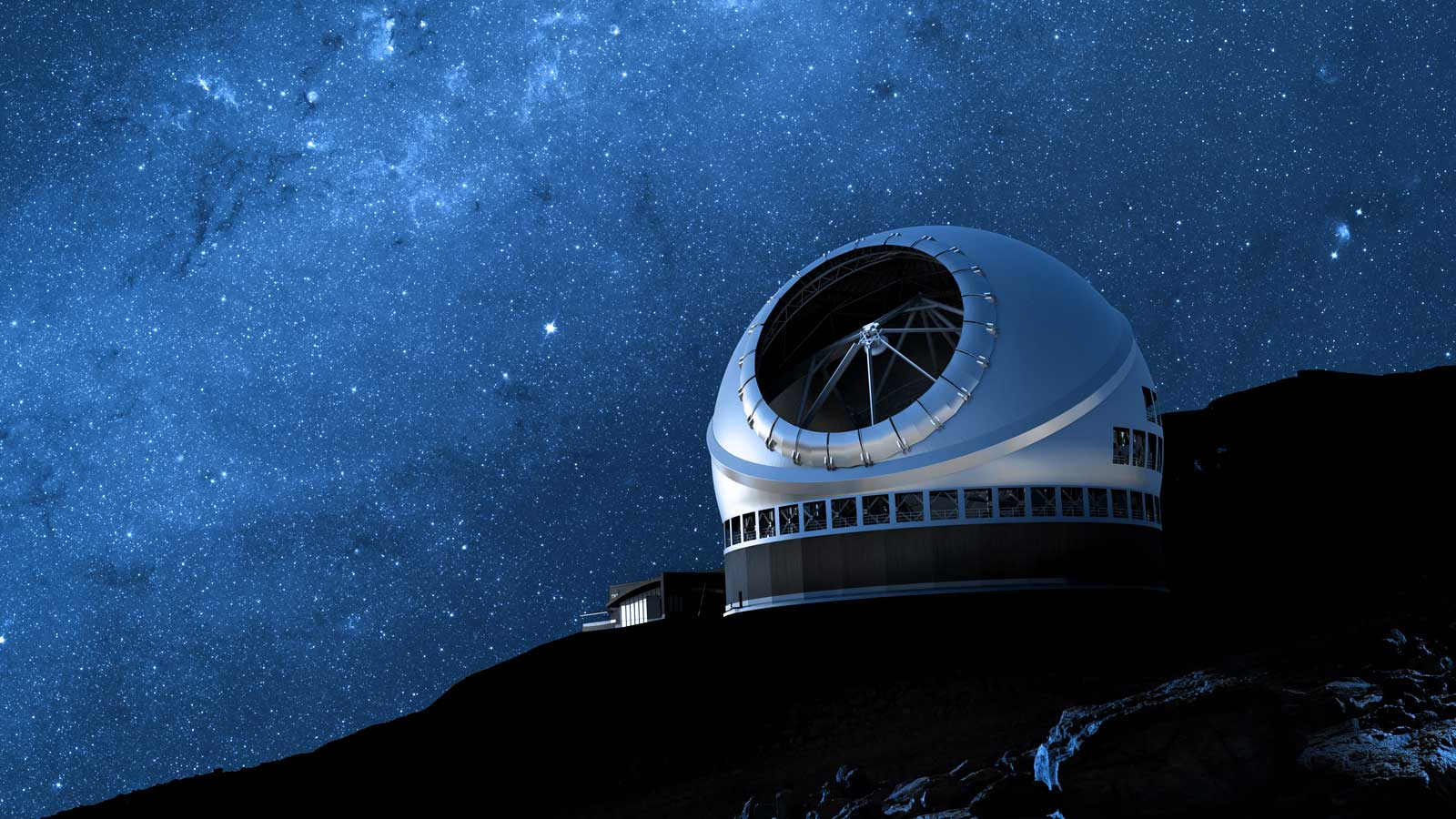

A realistic simulation of TMT observing the northern sky. The laser launched is part of the NFIRAOS adaptive optics system which provides the best image correction of the widest field of view.

A realistic simulation of TMT inside its dome. The instruments are on the left and right side of the telescope. Note the lack of gaps in the mirror; TMT's light collecting area is 90% of its diameter; the best of the ELTs.

A realistic simulation of looking at the WFOS instrument from the TMT primary mirror. WFOS is TMT's optical powerhouse of an instrument. It features imaging, longslit spectroscopy, and the ability to rapidly configure itself to take 96 individual spectra with the highest throughput of the ELTs.

A realistic simulation of light reflecting off the TMT tertiary mirror. This mirror reflects the light to the instruments; capable of moving from one instrument to the other in the time it takes to slew the telescope to the next object.

A realistic simulation of TMT inside its dome. This perspective is looking out from the telescope through the dome from the vantage point of the primary mirror. With the only ELT in the Northern Hemisphere, TMT will have access to parts of the sky the other two ELTs do not.

A realistic simulation of TMT dome at twilight. TMT's dome is incredibly efficient. It is the smallest of the ELT domes, With a smooth, curved shape, TMT's calotte dome reduces wind noise that shakes the telescope, allowing crystal clear images. The chosen shape and color help it blend in more with the surroundings.