During installation of the TMT telescope, metrology frames will be used for initial alignment of TMT Primary Mirror segments.

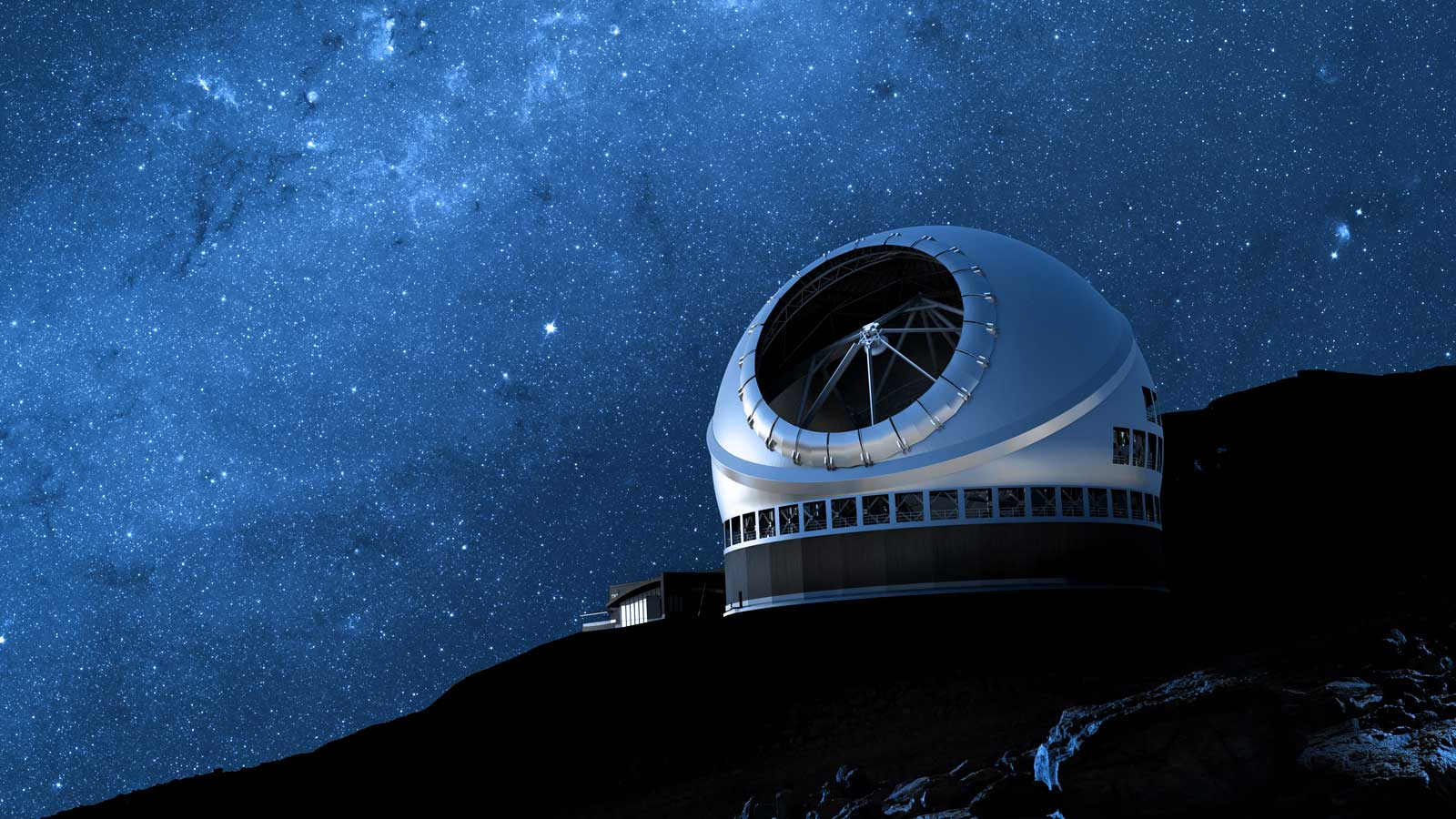

The TMT design utilizes a calotte-style enclosure, which minimizes the size and footprint of the facility, while allowing full movement of the telescope and optical systems.

The TMT Enclosure System is a dome structure housing the telescope. The three principal enclosure moving components are the rotating base, cap and shutter structures. Combined rotation of the rotating base and cap provides a range of required azimuth and zenith angles. The shutter is a rotating structure enabling opening and closing of the telescope aperture.

Fabricated by TMT-Japan, MSIT recreates a subset – approximately 1/70th - of the TMT primary mirror cell, and the segments it carries accurately recreate the unique hexagonal forms of the seven segments that will exist in the telescope in the same positions. Mirror segments in TMT are of 82 types – each one very slightly different – arranged in six identical sectors. MSIT contains segments from sectors D and E of the primary mirror.

Left to right: Bryan Smith (Quality Assurance and Testing Engineer), Alastair Heptonstall (Senior Opto-mechanical Engineer), Chris Carter (Telescope Controls Engineer), Alan Tubb (Associate Opto-mechanical Engineer), Ben Gallagher (M1 System Lead Engineer) and Nikhil Naik (Production Support Manager).

From left to right: A CLEARCERAM®-Z zero thermal-expansion glass mirror blank cast by OHARA Inc. in Japan, a prototype of TMT Primary Mirror Assembly, and a spherical glass precisely grinded by Okamoto Optics in Yokohama. Exhibits were featured at the Optics and Photonics International Exhibition, 25-27 April 2018 in Yokohama, Japan.

From Left: Tatsuki Endo (TMT-Japan), Janani Varadhachari (ITCC), Shuji Samizo (Nippon Express) and Nikhil Naik (ITCC)

All delivered TMT blanks are stored in India TMT Optics Fabrication Facility (ITOFF) inspection area, at IIA Crest Campus, Bengaluru.

The M3 system includes the M3 Blank, the M3 Mirror (a 3.5m by 2.5m flat elliptical mirror), the upper portion of the tertiary mirror (M3) system Tower, the M3 Cell Assembly, the M3 Positioner Assembly, the interface hardware between the M3 System and the Telescope Assembly, and support for receiving, assembly, inspection and verification of the M3 System onto the TMT Telescope at the Observatory. TMT M3S will approximately weigh 12 tons.

From left to right: Hu Haixiang, Luo Xiao, Qi Erhui, Hu Haifei Engineers from TMT China Changchun Group, in charge of the fabrication of TMT M3, are testing epoxy bonding pads on a 1/4 M3 prototype in Changchun lab.

Located in the center of the primary mirror, M3 is used to fold and steer the light path coming down from the secondary mirror, so the science beam can be delivered to any of the instruments active on the telescope.