In the previous article of this series on leviathans, we looked at how we think black holes have formed. Now, let's look first at how we can find these black holes, and second at how old we think they are.

Last week, a group of aspiring young astronauts went through a simulation of a space mission, looking for signs of extraterrestrial life in our Solar System. The children acted out a script based on NASA/JPL's deployment of the Curiosity Rover on Mars, and also the movie "Europa Report" for the landing on Europa.

Introduction "Towards thee I roll, thou all-destroying but unconquering whale; to the last I grapple with thee; from hell’s heart I stab at thee; for hate’s sake I spit my last breath at thee."

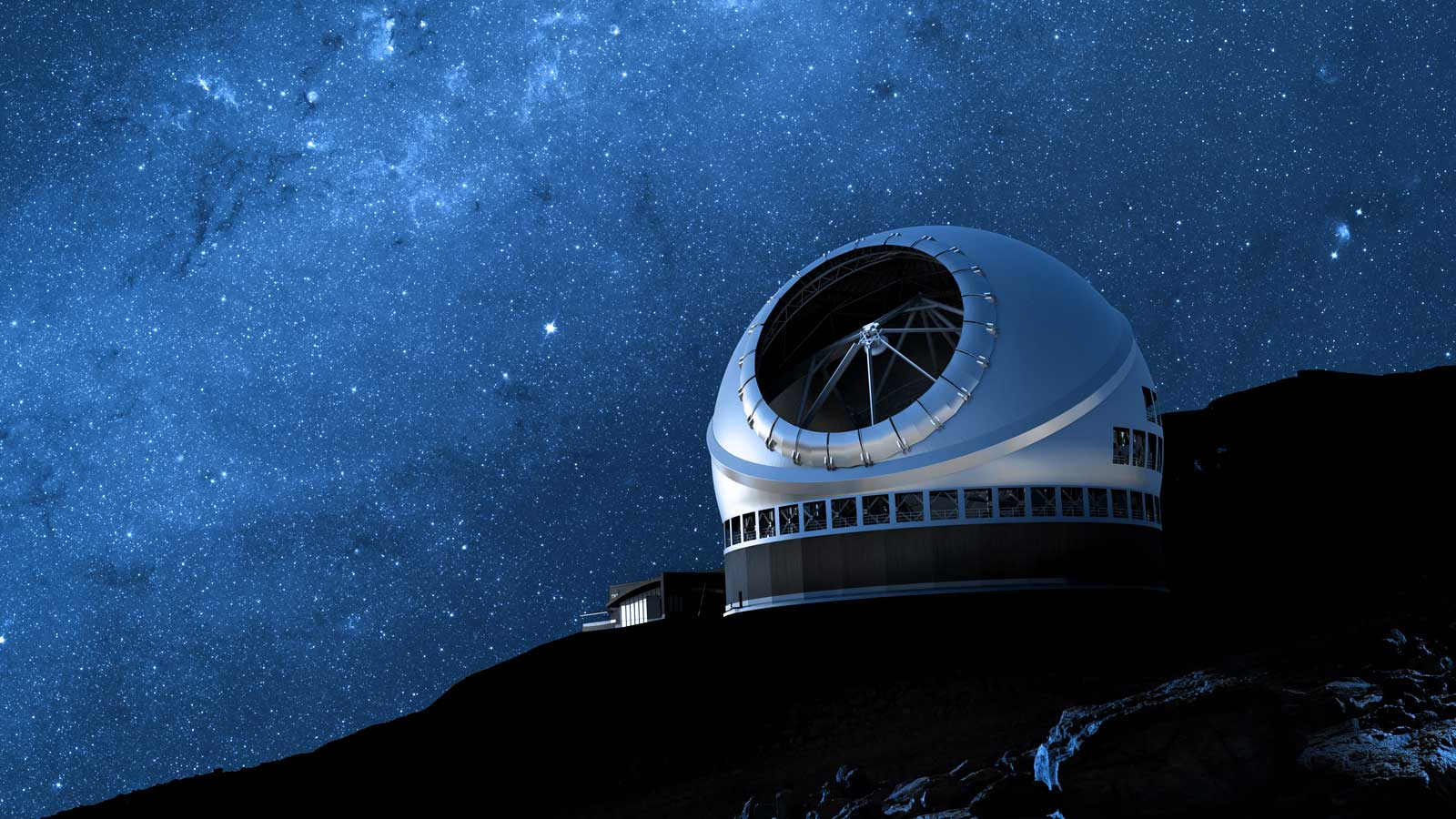

Dr Ravinder Bhatia, TMT Associate Project Manager, interviews with Annapurni Subramaniam, Professor of Astronomy at the Indian Institute of Astrophysics in Bangalore. She is the Indian project manager for the TMT observatory Software development.

A couple of weeks ago I was in Mumbai, to give a talk on TMT at "Vigyan Samagam—Pushing the Frontiers of Science”. The event was organized by the Indian government, to showcase India’s contributions to large international collaborations in fundamental science and research.

Dr Ravinder Bhatia, TMT Associate Project Manager, interviews with Dr Gelys Trancho TMT Senior Systems Engineer.

Dr Ravinder Bhatia, TMT Gerente de Proyecto Asociado, presenta una entrevista con Dr Gelys Trancho, Ingeniero Ejecutivo de Sistemas.

Dr Ravinder Bhatia, TMT Associate Project Manager, interviews with Dr Fengchuan Liu TMT Deputy Project Manager.

在TMT,我有幸能与来自许多不同国家和不同专业领域的专家一块工作。加入我和我一起认识这些同事,了解他们在TMT上所做的工作。我们还将探讨他们对于学生在职业选择方面的建议。今天,我们将与TMT项目副经理刘凤川博士对话。

Dr Ravinder Bhatia, TMT Associate Project Manager, interviews with Dr Warren Skidmore, TMT Instrument System Scientist.

Displaying posts 21 - 30 of 44 in total