The Tertiary Mirror Support System and Positioner Assembly (M3SSPA) has now successfully completed its Preliminary Design Phase after the Preliminary Design Review (PDR) was held at NOIRLab in Tucson, Arizona on August 11–12, 2025.

The Alignment and Phasing System (APS) team has progressed to the Final Design stage after successfully completing the Preliminary Design Review (PDR) for the APS Optical Bench and Instrument Control System (ICS).

The Thirty Meter Telescope (TMT) International Observatory (TIO) successfully completed a design review for a critical component of the primary mirror segment control system.

The TIO Secondary Mirror Support System and Positioner Assembly team successfully completed its Preliminary Design Review on 2024 July 15–17.

The TIO Monrovia Lab has recently received significant shipments of 140 warping harness cables and eight segment actuators from India TMT Coordination Center (ITCC).

Recently, Advanced Mechanical and Optical Systems (AMOS) in Belgium and TIO conducted a remote kick-off meeting for the preliminary design of the Tertiary Mirror Support System and Positioner Assembly (M3SSPA).

A Japanese delegation recently visited the India TMT Optics Fabrication Facility (ITOFF) in Bengaluru, India, where they were introduced to the newly installed polishing equipment at the Indian site.

In a significant development for the Thirty Meter Telescope (TMT) International Observatory (TIO), Glen Cole, former lead optical fabrication engineer at TIO, recently visited the India-TMT Optics Fabrication Facility (ITOFF) in Bengaluru, India.

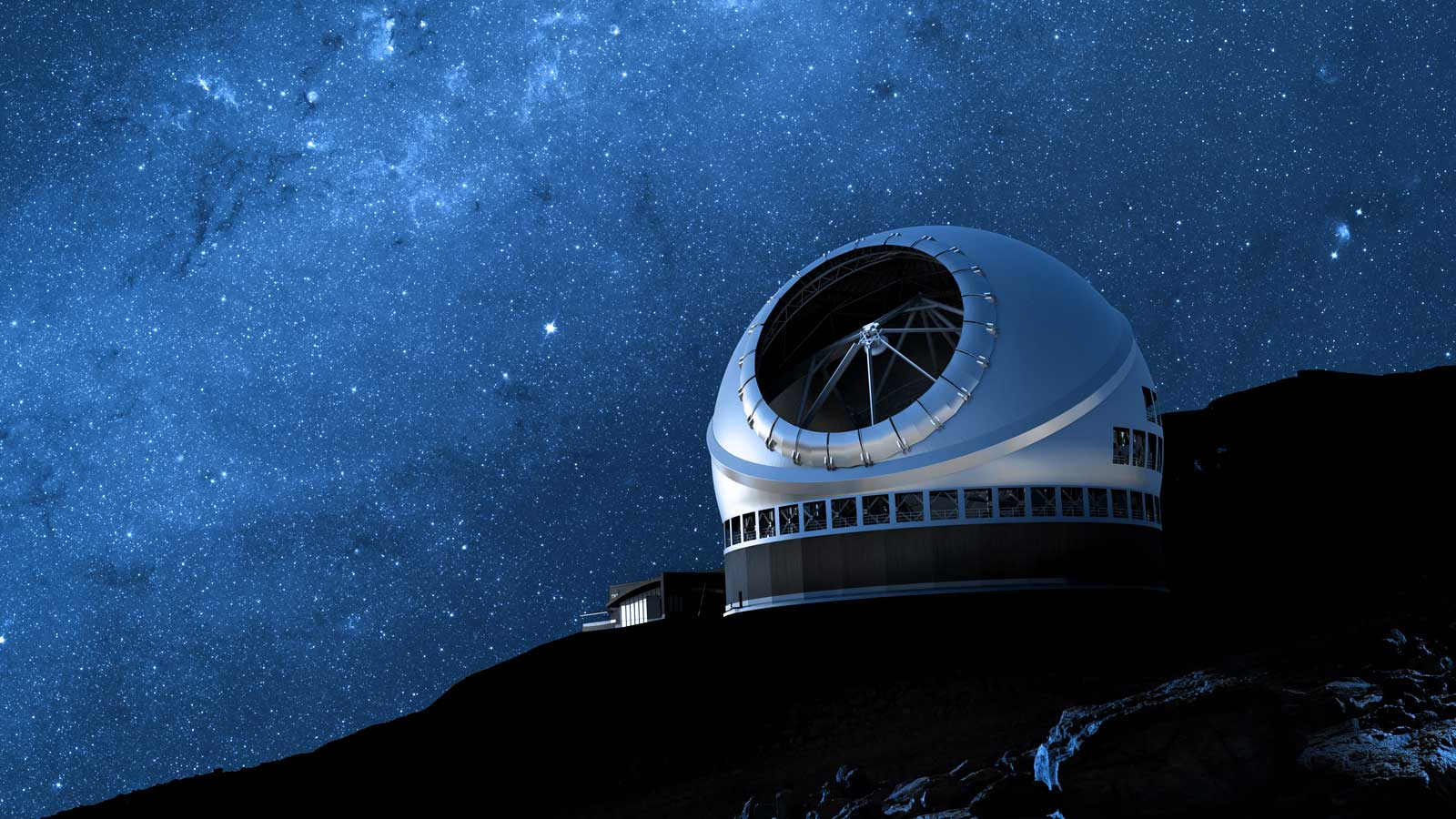

Today, the Thirty Meter Telescope (TMT) International Observatory (TIO) announces the completion of its 100th mirror segment. Ultimately, TIO will mosaic 492 of these segments to form an extremely large mirror 30 meters in diameter. This mirror will be the core component of the largest optical telescope in the Northern Hemisphere.

The Multi-Objective Diffraction-limited High-resolution Infrared Spectrograph (MODHIS) team recently conducted a midterm conceptual design review at the TMT Project Office in Pasadena on 30 January 2024. Led by Principal Investigator Dimitri Mawet (Caltech), co-Principal Investigator Michael Fitzgerald (UCLA), and Project Scientist Quinn Konopacky (UCSD), the MODHIS team showcased significant updates regarding MODHIS's design and expected...

Displaying news articles 1 - 10 of 72 in total